How to press heat exchanger plate and gaskets

The production process and management system used in the production workshop are consistent with international standards. Each plate produced has passed the test of European CE standards and ISO9001 quality management system. The processed plate has excellent performance and is free from defects.

1、 Inspection

First of all, starting from the raw material of a plate, the raw material manufacturers are also divided into domestic and foreign, full thickness and standard; When the raw materials arrive at the production workshop, the surface quality and material quality of the flat materials should be checked before warehousing.

2、 Cutting board

Then cut the plate according to the size of the target processing plate and cut off the excess leftovers. During the cutting, check the cut surface to ensure that there are no burrs, crimping and other problems. At the same time, the size after cutting should be checked to ensure that the size is accurate.

3、 Lubricating oil

After cutting the plate material, bagging/oiling and other operations need to be carried out according to the material of the plate. The purpose is to ensure that the thinning amount meets the relevant regulations in the process of pressing plate, and that the plate will not leak due to excessive deformation during use.

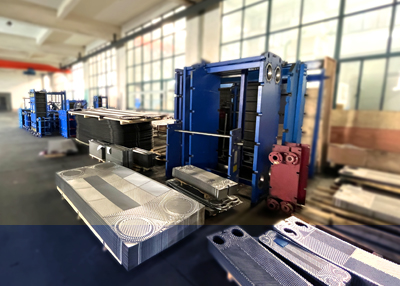

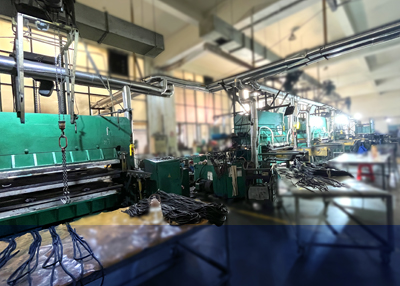

4、 Platen

Then press plates. The quality of the press plate has a high requirement on the accuracy of the mold. Only the press with high precision and high pressure can guarantee the quality of the pressed sheet. At the same time, the pressed sheet also needs to undergo a penetration test to ensure that there will be no cracks invisible to the naked eye that will cause quality problems. At the same time, the specific size and groove depth of the pressed plate should be checked to control the quality of the plate.

5、 Punching

After pressing, the corner holes of the plates need to be punched. At the same time, according to the design requirements of the first version, blind plate and special version of the heat exchanger, the punching positions are also different. Some plates are punched with three holes, some plates are punched with one hole, and the plates with different number of corner holes can match each other to form a multi-process heat exchanger. For some special working conditions, it can not only improve economic benefits, It can also play a very good heat exchange effect.

Seemingly simple sheet production process, in fact, the process is much more than expected, and there will be deviation if there is no step. We have a unique traceability system to ensure that each sheet can be controlled from the beginning of the raw material, and the quality can be guaranteed only by layer control during the production process.

The gasket of plate heat exchanger is the key component of heat exchange equipment. The working temperature of the plate heat exchanger is also the bearing temperature of the gasket, and the working pressure is also limited by the gasket. The sealing gasket not only seals the heat exchange medium to prevent it from leaking, but also prevents the materials from mixing with each other. In addition, the gasket is also a part prone to embrittlement under natural conditions. If the gasket becomes hard and loses its original ductility, the plate heat exchanger may not work properly.

Generally, the fixing form of gasket is divided into three types: adhesive type, inlay type and snap type. The sealing gasket and sealing groove of the plate heat exchanger must be completely consistent to achieve the sealing effect.

(1) Paste type: after applying sealant on the gasket groove, directly paste it into the installation groove of the heat exchange plate.

(2) Mosaic type: the heat exchange plate is designed with assembly holes, and the sealing gasket edge is designed with rubber nails. After placing the gasket into the sealing groove, insert the glue nail into the assembly hole.

(3) Clamping type: the sealing gasket has a hill-shaped buckle at the edge, and the sealing gasket is fixed on the heat exchange plate with a buckle.

Send Email

Send Email