Industrial process section heat exchanger unit

Plate heat exchangers play an important role in light and heavy industries such as pharmaceuticals and textiles. Why do most industrial heat exchangers choose plate heat exchanger instead of tube heat exchanger?

The plate heat exchanger has the function of heat exchange (heating, preheating, cooling, condensing). As long as it is the heat exchange between liquid-vapor and liquid-liquid, the plate heat exchanger can be used.

In this era of "energy saving and consumption reduction", which is also a major strategic issue in the new era, the role of plate heat exchangers in this area can not be ignored by any relevant enterprise, because it is related to their cost and profit, so every enterprise that wants to save energy and reduce consumption must be taken seriously.

Food factory all stainless steel sanitary heat exchanger

The extensive application of heat exchangers in the food processing industry not only enables food production and processing companies to process, package, transport and store food safely and reliably, but also saves resources, energy and capital for these companies.

Because these food-grade liquids can not only provide power for the heat exchanger, but also ensure the health and safety of consumers to the maximum extent in the process of driving heat conduction and convection.

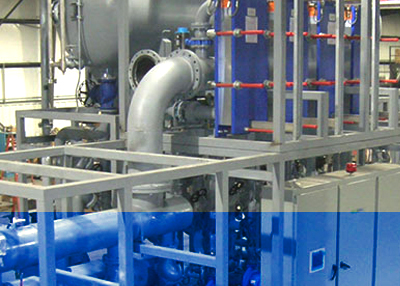

District heating station heat exchange equipment unit

The district heat exchange station is responsible for the heating of a district heat user, and is an important link between the preceding and the following in the urban central heating system. If the heat exchange station fails, it often causes problems in the heating of a certain area, and may even affect the normal operation of the entire central heating system. Therefore, attention must be paid to the design, operation and daily maintenance of the heat exchange station. When the heating is abnormal, it is of great significance to find and solve the problems in the heat exchange station in time.

Ammonia refrigeration supporting heat exchange equipment

Under the premise of ensuring the production process, which heat exchanger is used to make the best heat exchange effect between the media is a difficult problem for coking enterprises to solve. Through practical application, the answer is found that the plate heat exchanger is the most suitable type for ammonia water medium heat exchange heating. It is a relatively mature leading technology with less investment, less leakage, less clogging and scaling.

Sewage treatment wide channel heat exchanger

The heat transfer plate of the wide-channel sewage heat exchanger is made of stainless steel, which not only has high corrosion resistance, but also has an inclined plane. After polishing, dirt is difficult to deposit and adhere to the surface. The sewage flows from top to bottom along the heat exchange surface, and the sewage in the back continuously washes the sewage in front, making the heat exchanger difficult to scale, thus prolonging the service life and reducing the cleaning times of the heat exchanger.

The wide channel sewage heat exchanger is specially designed for sewage heat exchange. The sewage channel adopts the wide channel type, which has good internal trafficability and is not easy to block.

Power plant closed cooling water heat exchanger

The cogeneration projects in the power industry provide high-efficiency heat transfer products. Later, with the development of the power industry, more and more high-efficiency heat transfer products are applied to the closed cooling system, thermal system and heat recovery system of the power plant. These products provide optimization solutions based on the power plant system in solving material corrosion, heat energy recovery and utilization, and improve the power generation efficiency of the power industry.

Help the power plant to maximize the use of energy in many heating and cooling processes, and help them use waste heat and steam to generate new energy, and create energy in the way of energy conservation.

High-rise office building unit

Heat pipe is a kind of heat transfer element with good heat transfer performance. The tube is vacuum and full of working medium. When the evaporation end of the heat pipe is heated, the working medium will vaporize after evaporation. The vaporized medium will cool and heat up at the condensation end, condense into liquid, and fall back to the evaporation end. In this way, the heat transfer is completed by reciprocating. The heat pipe heat exchanger is composed of several heat pipes and shells. The heat pipe heat exchanger is divided into two-dimensional heat pipe, three-dimensional heat pipe, four-dimensional heat pipe and five-dimensional heat pipe, which can be used in different fields and environments to effectively achieve the effect of energy conservation and emission reduction.

Fine chemical production process heat exchange equipment

In the heat exchanger, the cold and hot fluids are separated by the partition, and there is a certain temperature difference, and a certain heat exchange will be formed between the two; It makes use of the heat balance knowledge of junior high school physics. The heat of high temperature objects will always be transferred to low temperature objects, thus transferring the heat from the hot side to the cold side. It is a device that can transfer heat energy from one fluid to another. It is widely used in chemical industry.

Send Email

Send Email